In recent years, the South Tyrolean stand has become “best practice” in alpine stand construction. But what exactly is a South Tyrolean booth? And what are the advantages or are there possibly also disadvantages? Chris Semmel has dealt intensively with the topic and also asked the inventors.

An article by Chris Semmel - first published in the trade journal mountaineering

The naming suggests that the South Tyrolean stand comes from beautiful South Tyrol. But that's not always the case with names, because the Viennese are known to be called Frankfurters in Vienna and vice versa. So, who invented the "South Tyrolean Stand"? We asked a South Tyrolean, someone who should know: Erwin Steiner. Erwin is a mountain guide and long-standing training manager of the South Tyrolean mountain guide training

The history - distribution of power

The South Tyrolean stand follows the three principles for alpine stands. In order of importance, these are:

- distribute forces

- No energy entry should a point break out

- Set up and dismantle quickly and clearly

The distribution of power

The overriding principle for alpine stands is the distribution of forces. Because a fixed point alone is often too weak to withstand the forces acting (the fall pull). There are several approaches to the distribution of power, which can be historically subdivided.

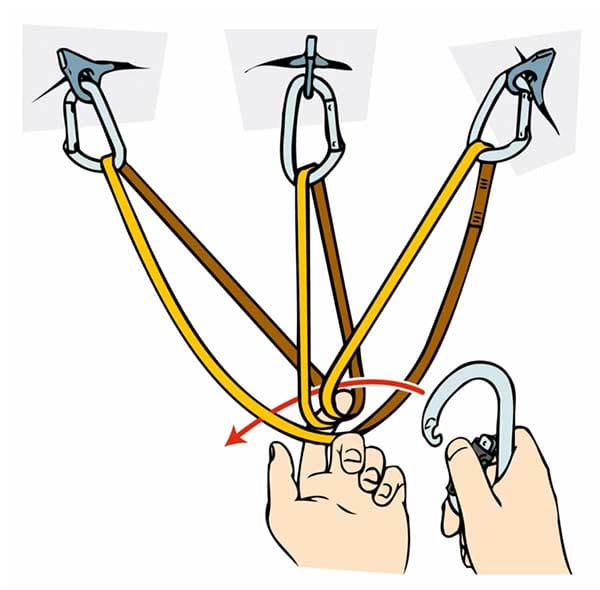

In the past, the so-called "compensation anchoring" was practiced in the Alpine region, also known as the "force triangle". A sling was hung in the fixed points, one of the two strands was twisted and the force was thus distributed to the fixed points. The rotation of the sling prevented one of the points of the central point carabiner from slipping out of the sling when it broke out (Fig. 3).

Brilliant at first glance and accepted doctrine in German-speaking countries until the 2000s. I was first confronted with criticism of this system in 1984 in Yosemite. If I initially thought a little arrogantly that they hadn't yet understood the principle, a conversation with a Yosemite local proved me wrong.

"The Americans in Yosemite never use this 'triangle of power'."

Chris Semmel

Due to the fact that in the Valley at the beginning of the 1980s - if at all - there were only rusty rivet-head bolts and fixed points usually had to be laid with wedges and cams themselves, the Americans were already aware at that time that a dangerous "energy input" could occur if a point erupted. into the system threatens.

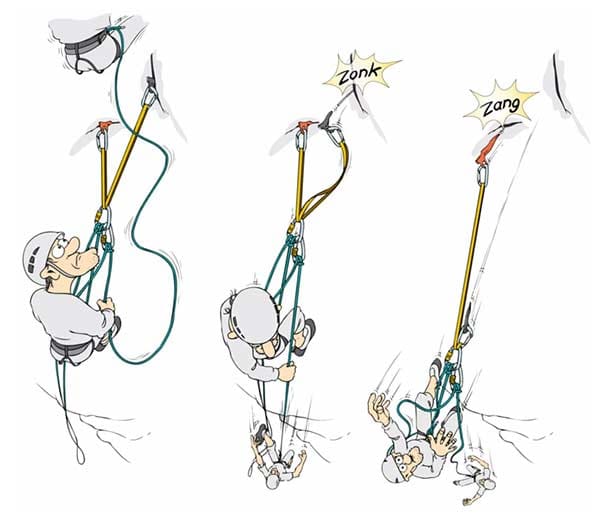

The energy entry

If one of the fixed points tears out, the lead climber falls further and loads the second, remaining fixed point with the entire energy of the fall. But not only the lead climber, but also the belayer falls into the remaining point with his self-belay.

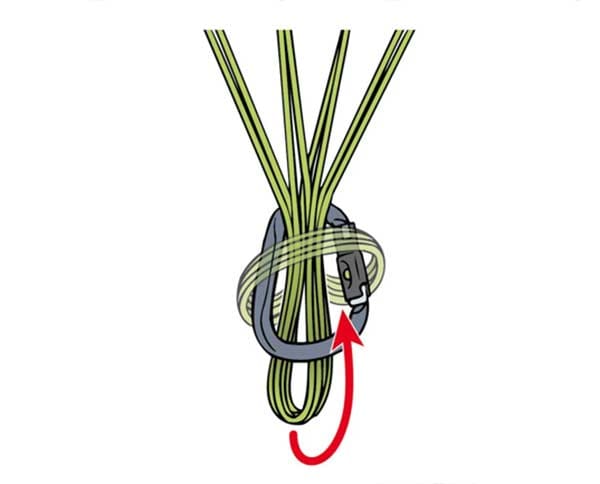

There are two masses falling into a statically acting noose. Two forces that add up. The force at the remaining fixed point is often greater than that which caused the first fixed point to fail. That was the reason why the Americans always built their stands with a so-called "overhand knot", i.e. a knotted overhand knot (Fig. 2).

It took a few more years before a change in thinking began in Europe. In the DAV security research we dealt with the topic from 2002 to 2004 and carried out measurements. Accidents were also collected which suggested that the second fixed point might have erupted because the "energy input" after the first erupted became too great.

Although we initially encountered considerable resistance, a rethinking slowly took place and the fixed triangle of forces prevailed. In 2006, the fixed distribution of forces became the doctrine of the DAV. At the same time, series connection at solid fixed points became socially acceptable.

"As early as 2008, the South Tyroleans were experimenting with a smarter method that is faster to set up and dismantle, which is now known as the South Tyrolean stand."

Chris Semmel

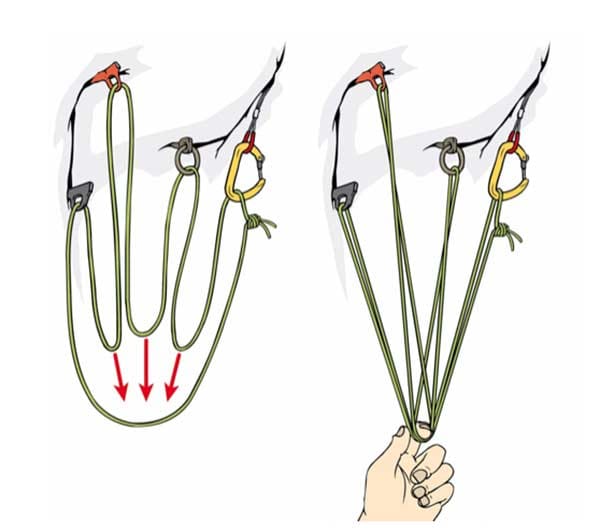

Construction of the South Tyrolean stand

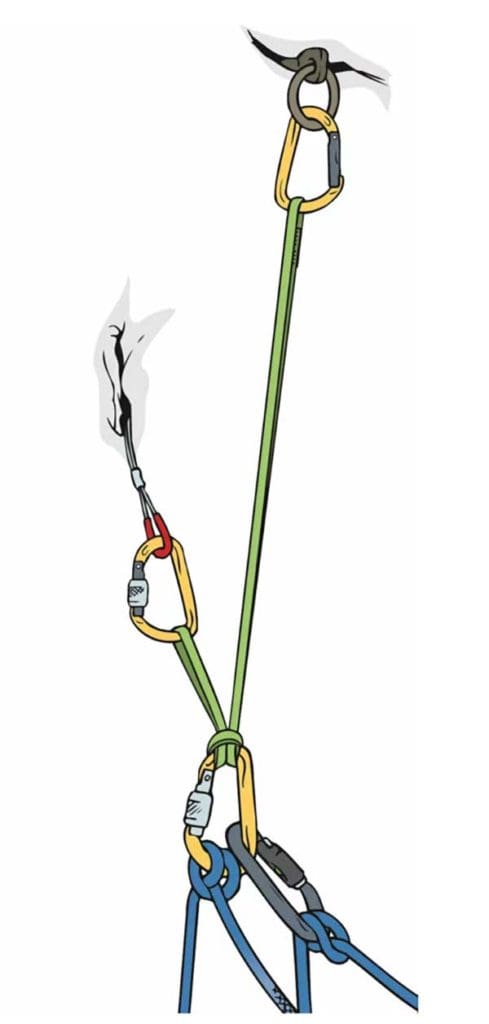

The "South Tyrolean stand" is set up depending on how many fixed points are available and whether a sewn sling or open cord material is used. Figures 4, 5 and 6 show the different setup options.

Open cord material is usually threaded directly into the hooks or through the hourglasses, wire cables from wedges and slings (existing hourglass and head slings and cams) are fitted with a carabiner. The direct threading of the hook eyelets with an accessory cord not only saves carabiners, but also avoids dangerous bending stresses on carabiners when hooks are driven in deeply.

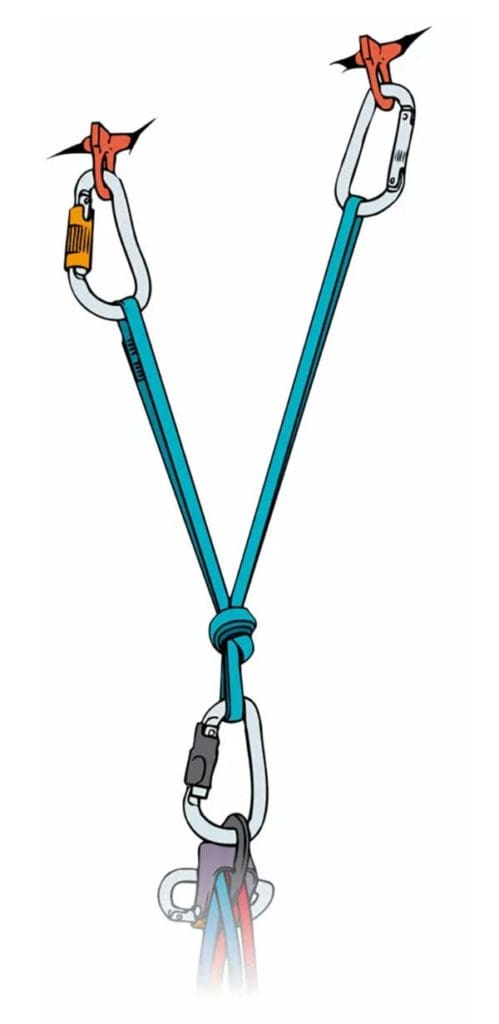

With two fixed points, a 120 mm sling is often used. This is threaded in the first (upper) hook with an anchor stitch and in the second (lower) hook twice (Fig. 4). The anchor stitch in the central point carabiner consists of six strands.

If the hooks are not threaded but attached with carabiners, the anchor stitch could also be formed from just four strands (Fig. 5). It is clear that the fewer strands in the anchor stitch, the sooner a loop starts to run if one of the fixed points breaks out.

Of course, the material used plays an important role. Because smooth Dyneema webbing slings start to run much earlier than polyamide slings or cord material with a polyamide sheath. But could "running" cause problems?

Problems with the "Südtiroler"?

Questions about this belay method are still frequently asked. Above all, the anchor hitch on the central point carabiner is often viewed with skepticism. This is especially the case when only two fixed points are connected and the anchor stitch is formed from only four strands (Fig. 5).

It is feared that if a point breaks out, the anchor knot will run on the central point carabiner. Burns or even a tear in the sling are feared. We (the author together with Stefan Blochum, the training manager of the Bavarian Mountain Rescue Service) investigated these questions and carried out static tensile tests and dynamic drop tests in the Mountain Rescue Center for Safety and Training (ZSA).

The Trials

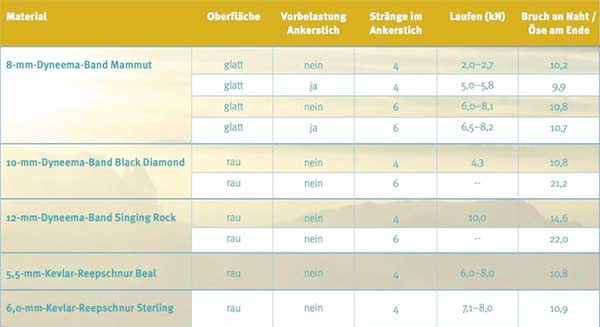

First, we tested the various slings in the form of "quasi-static" tensile tests on the tearing machine. We were interested in the throughput values of the various materials. So from what force does an 8 mm thin Dyneema webbing sling start to run in the anchor stitch, when a polyamide cord and when a Dyneema or Kevlar cord? We then tested the same slings in dynamic drop tests.

test description: Fall mass 95 kg / fall height 2,80 m / issued rope 180 cm / SIM hand 470 N / Edelrid Cobra rope, 10,3 mm

Statistical tensile tests

The results were more complex than initially thought. Because in addition to the number of strands and the material, the roughness of the loop, due to the weaving art, was also relevant. So whether one or two weft threads were used in weaving. Because the surface roughness influences the friction.

In addition, it makes a difference whether the anchor stitch was loaded loosely or pre-stretched. If the sling is loaded beforehand, e.g. B. because two people are hanging on the belay or because the fall tears out the first fixed point and the whole system is pulled (pre-stretched) as a result, this leads to the anchor stitch being pulled tight and thus to higher throughput values. In summary, we found the following:

- With an 8 mm thin Dyneema webbing sling with only four strands in the anchor knot (without preloading the knot), the anchor knot started to run at 2,0 to 2,7 kN. If the anchor hitch was preloaded and then pulled, the same sling only ran at 5,8 kN. If the structure shown in Fig. 4 was chosen, i.e. with six strands in the tie-stitch, the sling only began to move without preload at 6 to 6,5 kN.

- A 10 mm wide Dyneema webbing sling, unpreloaded and four strands anchor-stitched, began running at 3,4 to 3,9 kN.

- A 12 mm Dyneema sling made with one weft thread per weaving process and therefore rough only ran at 10 kN.

- Tears were observed when the sling could not continue through the carabiner in the end of the sling or the sewing. Here the breaking values were between 14,6 and 21 kN! So beyond all forces occurring in practice. The 5,5 and 6,0 mm Kevlar cords showed running between 8 and 10 kN (see Table 1: static tensile tests).

All in all, the results were reassuring, but raised the question of practical relevance. Because how strongly is an anchor stitch tightened if a fixed point breaks out and then the entire load acts on the remaining point? And how does the sling behave with regard to burns when the entire system is dynamically loaded? To further shed light on these questions, we performed further dynamic experiments.

Dynamic drop tests

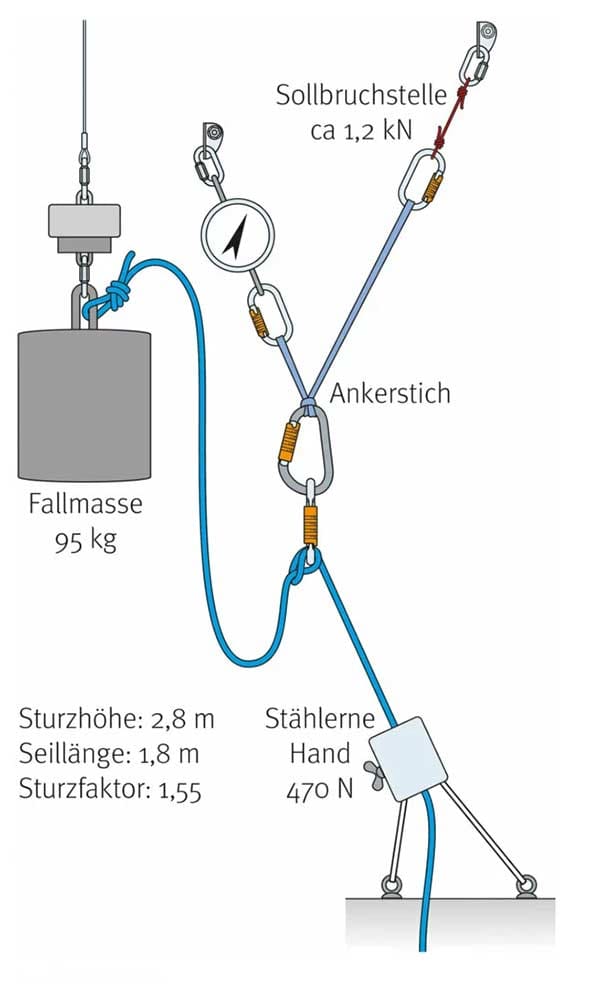

In the dynamic drop tests, the anchor stitch was always laid with only four strands. We carried out falls from a standing position in which one of the two standing hooks had a predetermined breaking point. This predetermined breaking point consisted of a single strand of 3 mm polyamide cord with two blind stitch eyes at the ends.

Our predetermined breaking point failed at around 1,1 to 1,2 kN. So that we didn't have to pull up our fall mass forever and due to the fact that the mountain rescue hall is not that high, we decided to keep the fall height rather small and to choose a large fall mass.

We used 95 kg iron mass as the fall weight with a free fall height of 3,2 m and a total rope length of 2,2 m. The fall factor was therefore 1,45 at the beginning. Since there was little rope available that could dynamically absorb energy, we expected very large force peaks.

We also used the "Simulated Hand" (SIM) with a very high manual force of 470 N on the HMS. The average hand force on the brake cable, on the other hand, is around 288 N. Only particularly strong contemporaries can achieve 450 or more Newton. Definitely a practical, but rather hard fall structure.

This was also confirmed in the first attempt, as our cable sheathing in the HMS tore right away. We then reduced the fall height to 2,8 m with 1,8 m of rope paid out (fall factor 1,55). So still a very hard fall, but less energy in the system.

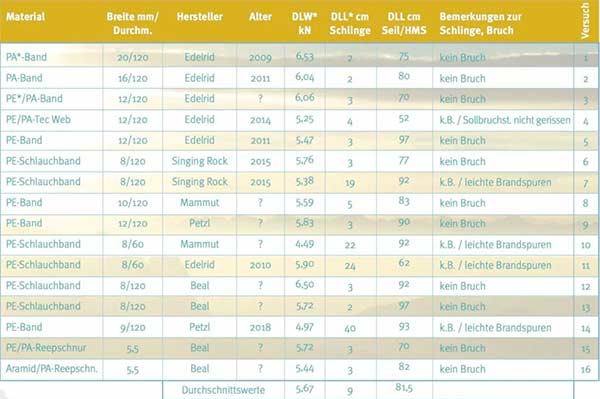

The results are listed in Table 2. The throughput values varied between 4,5 and 6,5 kN, the average was 5,7 kN. The slip length of the sling in the anchor hitch was between 2 and 40 cm and averaged 9 cm. No loop tears occurred. In 4 cases, slight, superficial traces of burns were observed, which occurred at slip lengths of 20 cm or more.

Sharp edges?

Another argument at the South Tyrolean stand relates to the construction with cord, in which the hook eyes are threaded directly. The fear was expressed that the sharp-edged eyelets of the standard hooks could damage the cord.

For this purpose, I already carried out tensile tests on sharp-edged tabs (e.g. BD 2018 mm ice screw tab) in 3. A 5,5 mm thin Kevlar cord held 12,54 kN here. So here, too, the all-clear can be given.

Conclusion

In summary, it can be said that the South Tyrolean belay structure, i.e. with an anchor point on the central point carabiner and directly threaded hook eyes, is extremely practical and offers sufficient safety reserves.

The method impresses with a very fast assembly and disassembly, avoids unnecessary knots that are very difficult to untie after loading, and avoids an energy input with optimal distribution of forces.

Thus, in recent years, this belay method has rightly become the "standard" for belays at questionable fixed points. Thanks to the South Tyroleans for their creativity with absolute practical relevance.

About the author

Chris Semmel is a mountain and ski guide and has worked for many years in DAV safety research.

About the magazine bergundstieg

Bergundstieg is an international magazine for safety and risk in mountain sports and illuminates the topics of equipment, mountain rescue, rope technology, accident and avalanche knowledge. Bergundstieg is published by the Alpine Associations of Austria (PES), Germany (DAV), South Tyrol (AVS) and Switzerland (Customer Service).

That might interest you

- Thunderstorms on the mountain: 5 tips to minimize risk

- Ice climbing: What to consider when getting started & tips from professionals

- How to look after your climbing equipment: tips and tricks

+ + +

Credits: Title picture as well as figures and tables in the text Mountaineering